Quickness and lowering costs are the most important things for a small business to grow and be successful in the long run. It’s possible for bigger companies to buy complicated ways to move things around, but most small companies don’t have the money or room to do so. Inclined conveyors are cheap and have a lot of useful features, so they are a good choice for small businesses.

Use of Space

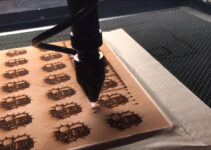

Source:youtube.com

Space is valuable for small businesses, so it’s important to get the most out of it. Moving things up and down on an incline conveyors belt saves important floor space. Forklifts and horizontal conveyors that are used today need a lot of floor room to move around. Unlike traditional horizontal conveyors, inclined conveyors take up very little space. This makes them ideal for shops or factories that don’t have a lot of room.

Lower labor costs

Because inclined conveyors move things automatically, less work has to be done by hand, so labor costs are lower. If a small business wants to run more smoothly and get more out of their workers, adding slope conveyors to their material handling systems can help. This technology not only increases output, but it also lowers the chance of mistakes made by people. This makes work more efficient and cuts costs in the long run.

Efficiency in terms of energy use

Incline conveyors typically use less energy than other types of equipment for moving things. Slope conveyors need less energy to run because they move things uphill with the help of gravity. For small businesses, this means less money spent on energy and running the business. Better conveyor technology, such as regenerative braking systems, reuses and recovers energy while the conveyor is slowing down. This makes energy use even more efficient.

Flexibility

Because inclined conveyors are flexible, small companies can change their material handling systems to fit their needs and the way they work. To move things from one floor of a building to another, load and unload cars, or connect to other machines, inclined conveyors can be changed to fit a lot of different needs. This way, small businesses can get better at what they do and grow as needed without having to buy a lot of new stuff.

Low Needs for Maintenance

Source:pinterest.com

Repairs and maintenance can take a lot of time and cost a lot of money for small businesses. Most of the time, inclined conveyors don’t need as much maintenance as other ways to move things. When you check on and do preventative maintenance on inclined conveyors on a daily basis, they can last longer. This makes sure they work well and have little downtime. Some makers also make designs that are simple for anyone to use and parts that are easy to get to. This makes it easier for small business owners and operators to do work on their machines.

A cheap way for small businesses to improve the way they move things is to use inclined conveyors. For small companies, these are great because they make the best use of space and cut down on labor costs. They’re also easy to move and don’t need much maintenance. You can help small businesses stay on budget and increase output by buying inclined conveyors. These machines also make work easier and help businesses grow in the long run. As of now, slope conveyors are very useful for small businesses that want to do well in the market because they are cheap and work well. With their affordability, efficiency, and adaptability, incline conveyors stand as indispensable tools for small businesses striving for success in today’s competitive landscape.