T-shirt printing has evolved from a simple way of showcasing creativity to a powerful means of self-expression and branding. Achieving accurate and vibrant prints is crucial for any successful t-shirt business or personal project. Precise t-shirt printing ensures that the design’s true essence is captured, elevating the overall quality of the garment. In this blog post, we will explore the key factors that contribute to precise techniques. From selecting the right materials to troubleshooting common mistakes, we will equip you with valuable insights to master the art of accurate t-shirt printing.

Choosing the Right T-Shirt Material for Printing Success

Selecting the appropriate t-shirt material is the foundation of successful t-shirt printing. The fabric’s composition, thread count, and color can significantly impact its appearance and durability. For best results, opt for 100% cotton or a cotton blend with a smooth surface. The fabric’s density should be sufficient to hold the ink without bleeding or spreading. Furthermore, consider the weave style, as looser weaves may require different methods. By choosing the right material, you set the stage for an impeccable print that stands the test of time.

Understanding Color and Design Considerations for Printing Accuracy

Color is the heart of any t-shirt design, and achieving precise colors requires attention to detail. Always work in CMYK color mode during the design process to ensure accurate color representation on the final pattern. Be mindful of color contrasts, as certain combinations may result in unwanted color shifts. Simplify intricate designs to avoid minute details getting lost during stamping. Conducting test prints on a similar fabric can reveal any design flaws and aid in refining the colors for optimal accuracy.

The Significance of High-Resolution Graphics

High-resolution graphics plays a pivotal role, in determining the quality and visual impact of the final product. Low-quality images result in pixelation and blur, diminishing the design’s clarity and appeal. High-resolution graphics, with a minimum of 300 DPI or vector format, ensure sharpness and precision during the process. They can be scaled infinitely without loss of quality, accommodating various sizes and enhancing versatility. With vibrant colors and intricate details, high-resolution graphics elevate the overall aesthetics of the t-shirt, leaving a lasting impression on the wearer and those around them. Whether it’s for personal expression or brand representation, investing in high-resolution graphics guarantees that your t-shirt designs make a bold and flawless statement.

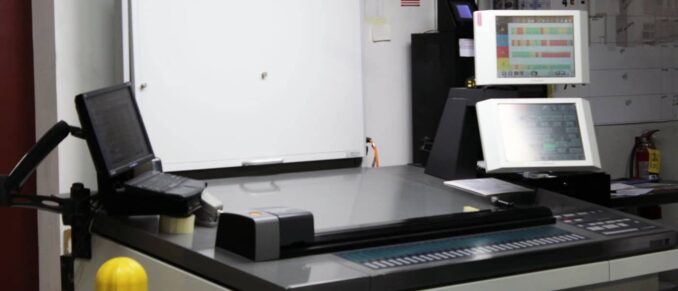

Proper Preparation: Pre-Treatment and Pre-Press Steps for Precision

Source: lasvegascolor.com

Before diving into this process, pre-treatment of the fabric is essential to create a receptive surface for ink adhesion. Pre-treatment removes any sizing or impurities that could hinder the process. Properly drying the fabric after pre-treatment is equally important, as excessive moisture can impact accuracy. Additionally, pre-press steps involve setting up the equipment correctly, calibrating colors, and aligning the fabric precisely for consistent prints. These preparatory steps lay the groundwork for a successful experience.

Selecting the Best Printing Method for Your Design and Fabric

Choosing the right method is pivotal in achieving precise results. The common techniques include screen stamping, direct-to-garment (DTG) printing, heat transfer, and sublimation. Each method has its strengths and weaknesses, depending on the complexity of the design and the fabric type. Screen stamping is ideal for simple designs with few colors, while DTG excels in intricate designs with multiple colors. Understanding the intricacies of each method will empower you to make an informed decision for your specific project.

A newer technique is direct-to-film printing, which complements these methods well, especially when used with advanced equipment like the Prestige XL2 printer.

Avoiding Common Ink and Color Mixing Errors

Ink and color mixing errors can turn a promising print into a disappointing one. Always use high-quality ink from reputable suppliers that match the fabric’s compatibility. Conduct ink mixing tests to ensure color consistency and accuracy before full production. Avoid using old or expired ink that can result in faded or distorted patterns. Cleanliness is also crucial, as any ink residue or contamination on the equipment can affect the color fidelity. By being diligent with ink and color management, you can sidestep common pitfalls and maintain precision.

Maintaining and Calibrating Printing Equipment for Accuracy

Source: tshirtplus.com.au

Regular maintenance and calibration of equipment is paramount for consistent accuracy. Cleaning the heads, checking the alignment, and calibrating colors are routine tasks that prevent potential errors. Temperature and pressure settings must be optimized for the specific fabric and ink used. Routinely inspecting and replacing parts will extend the lifespan of the equipment and ensure that it performs at its best, providing precise prints over the long run.

Testing and Sampling: Essential Steps Before Full Production

Before embarking on a large-scale run, testing, and sampling are crucial steps that prevent costly mistakes. Perform test patterns on the actual fabric to evaluate color accuracy, print placement, and overall quality. Sampling also aids in identifying potential issues with the chosen method or fabric compatibility. Adjustments can be made based on the results, fine-tuning the process for flawless full-scale production.

Curing, Drying, and Finishing with Care

Post-printing care is as critical as the process itself. Properly curing the ink ensures its longevity and washability, so invest in a reliable curing system. Avoid rushing the drying process, as hasty drying can lead to smudges or misalignment. Handle the finished garments with care to prevent accidental damage to the snaps. Additionally, storing the stamped t-shirts in a cool and dry environment preserves their quality and prevents ink degradation.

Troubleshooting Guide: Addressing Mistakes and Improving Future Prints

Source: canva.com

Even with meticulous planning, mistakes can still happen. Having a troubleshooting guide at hand allows you to address issues promptly and effectively. Common problems include color mismatches, ink bleeding, and poor adhesion. By identifying the root cause of these issues, you can implement corrective measures and improve future prints. Keep a log of troubleshooting steps and solutions for reference, saving time and resources in the long run.

Conclusion

In conclusion, achieving precise t-shirt printing involves a comprehensive understanding of materials, colors, methods, and post-printing care. Attention to detail, coupled with careful preparation and maintenance, ensures that each print is a work of art. By avoiding common mistakes and learning from past experiences, you can elevate your t-shirt printing game and deliver impeccable results that impress customers and clients alike.