Flame treatment, a process used to increase material adhesion, is generally acknowledged for its efficiency in improving bonding capabilities. However, its innovative use techniques have evolved, providing distinct benefits and opening up possibilities. The Ribbon Burner is one such application that has gained popularity.

The Ribbon Burner is a specialty treatment device that uses numerous burners placed in a ribbon-like pattern to generate a long, narrow flame. The innovative design enables accurate and effective material treatment across a large area.

In this post, we will look at some of the most unique applications of flame treatment that you should be aware of. It has various applications in various sectors, from surface modification to material activation.

Understanding Flame Treatment

Source: thierry-corp.com

- Flame treatment is a method of improving material adhesion. It entails exposing the material to a controlled flame.

- The heat from the flame generates molecular changes on the surface of the substance. It improves the material’s wettability and adhesive qualities.

- Plastics, polymers, and composites are common materials treated with it. This method modifies substrate surface energy, making them more appropriate for bonding and coating applications.

- This increases the surface energy of low-energy polymers such as polypropylene and polyethylene.

- It is a versatile process that can be applied to a wide range of materials and provides a diverse alternative for modification.

Application of Flame Treatment

Adhesive Bonding Surface Activation

Flame treatment is commonly used to activate surfaces before adhesive bonding. Molecular changes occur when a material is subjected to a controlled flame, resulting in enhanced surface energy. It is especially advantageous for low surface energy materials such as polyolefins (e.g., polyethylene and polypropylene), which is notoriously difficult to bind.

Surface Cleaning and Degreasing

It is an excellent surface cleaning and degreasing process. The high temperature of the flame aids in the breakdown and evaporation of pollutants, oils, and greases on the object. This technique removes possible adhesion obstacles, leaving a clean and responsive surface for subsequent processing or bonding.

Improving Adhesion of Labels and Decals

Flame treatment is utilized in the labeling industry to enhance the adhesion of labels, decals, and stickers onto various surfaces. Treating the surface with a controlled flame increases the surface energy, allowing the adhesive on the tags to form a stronger bond with the substrate. This ensures that the labels remain securely attached, even under challenging conditions.

Enhancement of Hydrophilicity

Heat treatments can change the outermost characteristics of materials, increasing their hydrophilicity. It improves the wetting and spreading of liquids on affected areas by changing their outermost energy. This application is helpful in optics, healthcare, and filtration, where better liquid interaction is sought.

Promoting Ink Adherence in Flexographic Printing

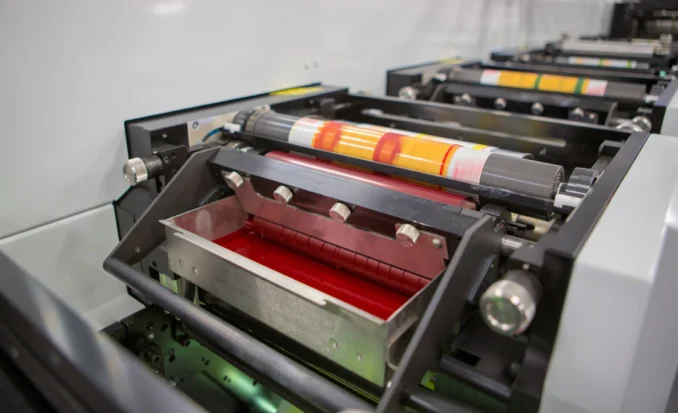

Source: blog.luminite.com

This treatment is critical in flexographic printing for promoting ink adherence on plastic films and other substrates. The substrate’s surface energy is enhanced by exposing it to the flame, allowing for greater ink transfer and adherence. Consequently, prints are crisper and more colorful, with improved adherence and durability.

Surface Preparation for Lamination

Before laminating materials together, a surface preparation procedure called flame treatment is used. The energy is increased by exposing it to the flame, resulting in greater adhesion between the layers. This phase assists in the elimination of any bonding difficulties caused by impurities or low energy, resulting in a strong and dependable lamination.

Enhancing Tape and Film Adherence

It improves the adherence of tapes, films, and adhesives to diverse surfaces. The surface energy is raised by changing the surface characteristics by flame treatment, allowing for improved bonding between the adhesive and the substrate. Consequently, tape or film adhesion is enhanced, ensuring secure attachment for packing, sealing, or bonding applications.

Coating Surface Activation

The flame treatment activates surfaces before coating applications such as painting, varnishing, or adding protective films. The surface energy is increased by exposing it to the flame, allowing for improved wetting and adherence of the coating material. This results in improved coating performance, such as increased durability, resistance to peeling or flaking, and a more appealing overall look.

Increasing Gasket and Seal Adherence

This treatment improves the adherence of gaskets and seals to surfaces. The surface energy of the mating surfaces is increased by heating them with a controlled flame, guaranteeing a strong binding between the gasket or seal and the substrate. This increases the seal’s efficacy, lowering the danger of leaks or failures.

Surface Preparation for Overmolding

It is utilized as a surface preparation step before over-molding procedures, which involve molding one material onto another. The surface energy is raised by exposing it to the flame, which improves the bond strength between the base material and the over-molded substance. This creates a strong and long-lasting connection, avoiding delamination or separation during usage.

Activation of Composite Materials

Before bonding or coating, It is used to activate the outer area of composite materials, notably carbon fiber-reinforced composites. The outer energy is raised by treating it, enabling stronger bonding between the composite layers. This improves the composite construction’s performance and structural integrity.

Conclusion

Source: flametreaters.com

In conclusion, flame treatment expands applications beyond conventional bonding by demonstrating that it is a flexible and affordable method of surface modification. Its applications in printing, coating, 3D printing, plastic painting, and textiles show its cutting-edge potential. One of its primary benefits is enhancing coating performance, ink adherence, adhesion, and compatibility. It produces remarkable results in terms of adherence and product longevity.

Flame treatment is an excellent method for raising quality standards. Its cost, environmental friendliness, and versatility make it appealing. Flame treatment is a desirable alternative, particularly for businesses looking for excellent treatment choices at an affordable price. This technique lessens the impact on the environment and improves the safety of the working environment.